There are a handful of printing methods that cover a huge assortment of display products that Camelback Displays carries. Each has advantages and disadvantages depending on the needs of the client and the function of the product.

Camelback’s Print Methods

Silk Screen Printing:

Silk screening is a process that uses gobs of ink that are pushed through a screen to form an image onto a surface. Inks are mixed to form Pantone colors and there is a high degree of accuracy in matching a particular corporate color. This low-tech process involves making a transparency of the art to be silkscreened which is “burned” onto a light sensitive emulsion coated screen by exposing it to light. This makes opaque areas that ink cannot pass through and is a negative of the art. Once the screen is cleaned, it is then mounted to the silk screen printing press and the fabric or other media is mounted to platen, which is a hard flat surface. Once the screen is pushed down on top of the platen, ink is then squeegeed onto the surface of the scree and onto the media below. Afterwards, the ink has to be cured under a heat lamp. If multiple colors are required, the process is repeated.

Display products that use silk screening include director’s chairs, table covers, signage, tent canopies, promotional products and clothing.

Advantages: Depending on the screen, fine details can be shown and beautiful printing effects can be achieved. Also, many companies require a close color match to their corporate colors and silk screening achieves this because of the way the inks are mixed. When cured correctly, the inks used are very durable and will hold up for years with normal use.

Inkjet Printing:

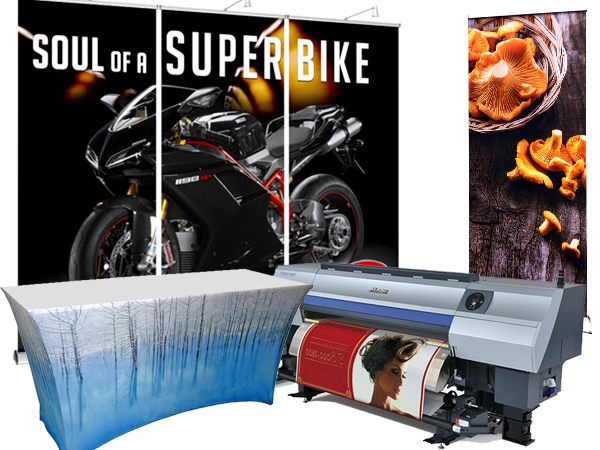

Inkjet printing is probably familiar to anyone who has used a color or black & white desktop printer. This form of printing produces an image by shooting dots of color onto the film, paper, vinyl or other substrate media that is needed. High resolution, photorealistic results can be attained with rich, vibrant color rendering. Inkjet printing is extremely popular and is used on many display products. Inkjet printers use aqueous inks, solvent inks and UV-curable inks. Solvent inks resist fading in daylight, are water resistant and are used in banners along with other outdoor printed products. Most of our inkjet products use high quality Solvent inks. Aqueous inks offer a larger color pallet but fade easily in prolonged sunlight. UV-curable inks are expensive to use, but produce the most durable image of all three.

Display Products that use inkjet printing include Banner Stands, Banners, Trade Show Displays, Pop Up Displays, Hybrid Displays, Directors Chairs, Full Color Flooring, Detachable Exhibit Graphics, Exhibit Furniture, Kiosks, Merchandiser Displays, Hanging Banner Signs and Sign Holders. If Direct-to-Substrate Flatbed Inkjet Printers are used this list can be expanded to printing on the surface of practically anything that is flat; from wood and metal to glass. We offer display products that utilize this type of direct printing on Sintra, which is a type of PVC display panel that is used for different types of displays and signage.

Advantages: Inkjet printing is so versatile that you can print on many substrates and surfaces. Solvent inks are durable, water & fade resistant. Also, it is more affordable than other types of full color printing used in other industries. Colors turn out great and there is plenty of sharp detail. Hard copy proofs are usually available to judge color and clarity.

Dye Sublimation Printing:

For our company, dye sublimation is full color printing on a variety of fabrics. Dye-Sub printing is similar to inkjet printing in that the transfer image is an inkjet print, but that is where the similarities end. For most the products we use it on, once the transfer print is produced and then the image is applied to whatever fabric we are using with heat and pressure.

The image is actually bonded directly onto the fibers of the fabric, creating a full color fabric that can be used for table throw covers, spandex contour covers, director’s chairs, banner stands, fabric walls, hanging signs, canopies, hybrid exhibits and a number of other display products.

Dye sublimated products create a vivid and attractive display. The colors are vibrant are are sure to make your display needs stand out in the crowd. We offer a wide selection of dye sublimated products.

Advantages: Graphics can usually be folded for storage or shipping. Standard graphics have to be rolled, fit into a case or box and end up using a lot more space. Depending on the printer and the process, colors are beautifully printed and high impact easy to use graphics are the result. Also, fabric graphics can go places that standard laminated inkjet graphics cannot. Fabric dye sublimated graphics can wrap around aluminum frame shapes, tuck into grooves (using rubber gaskets) and stretch across display components to form unique looking solid shapes.

Vinyl Heat Transfer Cut-Outs:

Using different colored vinyl and a type of printer called a plotter that sports a cutting knife rather than a print head, logos or art can be cut and adhered to different products. Just picture the cut-out letters that someone might use on a storefront glass door to post hours or an address on a mailbox… It’s the same concept. On a plotter, intricate logos and artwork can be cut from the vinyl and applied to almost any flat surface that it can stick to. Some use a thin layer of glue similar to what is used on tape and others are applied with a heat press. Since this isn’t actually printing, you are limited to the colors of the vinyl that is currently available, but that works for many applications for canopies, table throws & skirting, director’s chairs, counter tops, display panels, flooring and a slew of other products.

Advantages: Cost is a big factor in displays and exhibits and sometimes a cut-out logo is the simplest and easiest approach to solve the problem of adding a logo to something. Placement of vinyl cut-outs is very versatile since you don’t always have to install them with heat. There are a huge variety of uses and effects that can be achieved with this simple process since they can be installed on fabric, wood, metal, tiles, sheetrock and much more.

Vinyl Heat Transfer Prints:

Vinyl prints are very similar to cut-outs, except that full color printing is used to make the vinyl prints; which can also be cut into shapes. Some products may combine an inkjet printer with a plotter to make a full color print that is cut into a variety of shapes: a circle, oval or intricate shape. All of the same benefits that vinyl cut-outs offer can be used with full color vinyl prints. In fact, all the same display products use them in the same way.

Inlaid Logos:

Inlaid logos that we produce are usually in flooring products such as logo mats, carpeting and interlocking flooring. Inlaid logos use the actual flooring or carpet to make the image. Our most popular inlaid logos are made with a water jet cutter that cuts out individual elements of a logo along with the background that the logo is going on. Once combined like puzzle pieces, the result is a seamless logo, art or message combined onto carpet or floor tiles.

Advantages: When applied to flooring, the results look clean and professional. Because different colors of the same carpet or tile are used to make a logo, there is no loss of floor utility. In other words, someone can walk all over the logo just like it is part of the floor (because it is).